A Deep Dive into Modern Shale Gas Recovery Technologies

Shale gas extraction represents one of the most significant technological achievements in energy production. Unlike conventional natural gas, which flows freely through porous rock, shale gas is trapped in tight formations with permeability measured in nanodarcies—making it virtually impenetrable to traditional methods. Modern recovery technologies have not only unlocked this resource but have fundamentally altered global energy markets and geopolitics in the process.

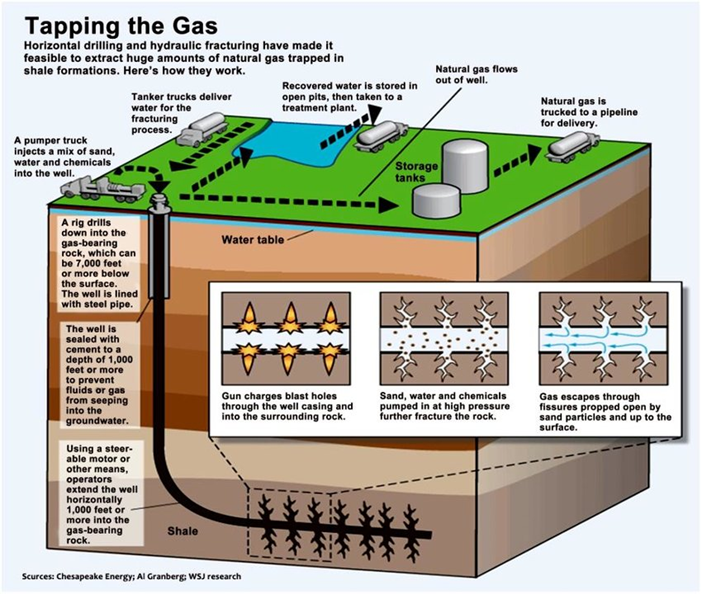

The Foundation: Combining Horizontal Drilling & Hydraulic Fracturing

The breakthrough in shale gas recovery came from combining two established technologies in a novel way. Neither horizontal drilling nor hydraulic fracturing is new—both have existed for decades. What changed was the precision and scale at which operators could deploy them together.

Horizontal Drilling: Maximizing Formation Contact

Horizontal drilling allows an operator to drill vertically to a target depth, then gradually curve the wellbore to run parallel with the shale formation. Modern directional drilling systems can extend this horizontal section for over 10,000 feet, whereas early attempts struggled to exceed 1,000 feet.

This technique relies on Rotary Steerable Systems (RSS) and Measurement While Drilling (MWD) tools that provide real-time feedback. According to research published in the Journal of Petroleum Technology, horizontal wells in the Marcellus Shale contact 10-15 times more reservoir rock than a vertical well, which translates directly to higher production rates (Kumar et al., 2023).

Operators use geosteering—adjusting the drilling path in real-time based on geological data—to keep the wellbore within the most productive zones. This requires a sophisticated interpretation of gamma-ray logs, resistivity measurements, and formation pressure data transmitted from downhole sensors.

Hydraulic Fracturing: Creating Permeability

Hydraulic fracturing, or “fracking,” creates permeability where it does not naturally exist. The process involves pumping fluid into the formation at pressures that exceed the rock’s fracture gradient—typically 0.7-1.0 psi per foot of depth. At 8,000 feet, this means surface pressures can reach 8,000-10,000 psi.

Modern fracking operations use “plug-and-perf” completions to fracture the horizontal well in discrete stages, often 20-40 stages per well. Each stage targets a lateral length of 200-300 feet. The fracturing fluid—roughly 90% water, 9% proppant (typically sand), and 1% chemical additives—creates fractures that can extend 300-500 feet from the wellbore.

Table 1: Composition and Purpose of Hydraulic Fracturing Fluid

| Component | Percentage | Primary Function | Common Examples |

| Water | 88-92% | Fracture creation and proppant transport | Freshwater or recycled water |

| Proppant | 8-11% | Holds fractures open after pressure is released | Sand, ceramic beads, resin-coated sand |

| Friction Reducer | 0.05-0.1% | Lowers pumping pressure and protects equipment | Polyacrylamide polymers |

| Biocide | 0.001-0.01% | Prevents bacterial growth in the wellbore | Glutaraldehyde, bronopol |

| Scale Inhibitor | 0.01-0.05% | Prevents mineral precipitation | Phosphonates, polymer inhibitors |

| pH Adjuster | 0.01-0.1% | Optimizes fluid chemistry | Sodium carbonate, acetic acid |

The choice of proppant significantly impacts long-term production. While natural sand remains the most economical, ceramic proppants offer higher crush resistance at depths greater than 10,000 feet, where closure stresses can reach 10,000 psi. Recent developments include resin-coated proppants that prevent flowback while maintaining conductivity.

Monitoring and Optimization Technologies

Microseismic Monitoring: Seeing the Invisible

Microseismic monitoring detects the acoustic emissions of fractures as they propagate through rock. Sensitive geophone arrays placed in offset wells or on the surface triangulate these micro-earthquakes (typically magnitude -3 to 0) to map fracture geometry in real-time.

This technology revealed that hydraulic fractures do not always propagate as simple, planar features. Instead, they form complex fracture networks influenced by natural fractures, stress variations, and rock properties. Data from the Barnett Shale showed that effective fracture half-lengths were often 200-300 feet, far shorter than the 500+ feet initially assumed by operators (Fisher & Warpinski, 2012, SPE Hydraulic Fracturing Technology Conference).

Operators use this information to optimize stage spacing, adjust pumping schedules, and avoid parent-child well interference—where new wells inadvertently drain older ones or create fractures that do not connect to the wellbore.

Fiber-Optic Sensing: Continuous Surveillance

Distributed Acoustic Sensing (DAS) and Distributed Temperature Sensing (DTS) use a fiber-optic cable as thousands of virtual sensors along the wellbore. These systems detect sound and temperature changes with a spatial resolution as fine as 3 feet.

During fracturing, DAS can identify which perforation clusters are taking fluid and which are not—a critical insight, as industry studies show 20-40% of clusters contribute minimally to production. Post-fracturing, permanent fiber installations monitor production profiles, detect water breakthrough, and identify opportunities for remedial work.

Advanced Drilling Fluids and Completion Designs

Modern drilling operations use water-based muds engineered for shale compatibility. These fluids maintain wellbore stability in reactive shales while minimizing formation damage. Key additives include:

- Polymers that encapsulate shale cuttings, preventing them from dispersing.

- Lubricants to reduce friction in extended-reach horizontal sections.

- Sized calcium carbonate to provide a temporary bridge without causing permanent damage.

Completion fluids have evolved from simple KCl brines to engineered systems using cesium formate or high-density brines to control high formation pressures. These fluids must be compatible with fracturing operations and not damage natural or induced permeability.

Table 2: Comparison of Shale Gas Recovery Technologies

| Technology | Primary Function | Typical Cost Impact | Production Impact | Technology Maturity |

| Horizontal Drilling | Maximizes reservoir contact | 20-30% of well cost | 10-15x vs. vertical well | Mature |

| Multi-Stage Fracking | Creates permeability | 40-50% of well cost | Essential (enables production) | Mature |

| Microseismic Monitoring | Fracture mapping & optimization | 2-5% of well cost | 5-15% improvement | Established |

| Fiber-Optic DAS/DTS | Production surveillance | 1-3% of well cost | 10-20% through optimization | Growing Adoption |

| Rotary Steerable Systems | Precise directional control | 5-10% of well cost | 8-12% improvement | Mature |

| Advanced Proppants | Maintains fracture conductivity | 15-25% of completion cost | 15-30% improvement | Established |

Emerging Technologies Reshaping the Industry

Artificial Intelligence and Machine Learning

The use of AI in shale gas recovery has moved from experimental to operational. Machine learning algorithms can now predict formation properties from limited data, optimize drilling parameters in real-time, and forecast production decline curves with greater accuracy than traditional type curves.

Operators use neural networks trained on thousands of wells to identify “sweet spots”—areas with superior production potential within a broader formation. In the Permian Basin, AI-guided landing zone selection has improved EUR (Estimated Ultimate Recovery) by as much as 18% compared to traditional geological analysis alone (Hart Energy, 2024).

Waterless Fracturing Alternatives

Environmental concerns and water scarcity have driven the development of alternative fracturing fluids. Technologies being evaluated include:

- LPG (Liquefied Petroleum Gas) Fracturing using liquid propane or butane, which vaporizes during flowback, eliminating wastewater.

- CO2-Based Fracturing, which combines carbon sequestration with enhanced production.

- Foam Fracturing using nitrogen or CO2, which can reduce water requirements by 50-80%.

While water-based fracturing remains dominant due to cost advantages, these alternatives show promise in water-constrained regions or where wastewater disposal is challenging.

Re-fracturing: Unlocking Stranded Resources

Many early shale wells were completed with conservative designs by today’s standards—fewer stages, less proppant, and lower treatment pressures. Re-fracturing technologies re-stimulate these wells, often by isolating the original completion and creating new fractures.

Studies from the Eagle Ford Shale show that re-fractured wells have recovered an additional 30-60% of their initial EUR, though results vary significantly with formation properties and the quality of the original completion (SPE Production & Operations, 2023).

Integration: The Modern Shale Gas Workflow

Successful shale gas development requires the integration of these technologies into a cohesive workflow. The process typically follows this sequence:

- Geological Characterization using 3D seismic and core analysis to identify the optimal landing zone.

- Pad Development allowing for multiple wells from a single surface location.

- Precision Drilling using RSS and geosteering to place the lateral within the target zone.

- Completion Design Optimization based on geomechanical modeling and offset well performance.

- Frac Job Execution with real-time monitoring and adjustments.

- Production Monitoring using permanent downhole monitoring and surface facility optimization.

This integrated approach explains why operators in mature fields like the Permian and Marcellus consistently achieve EURs that are 2-3 times higher than early development wells, despite targeting similar geology.

Summary

The next generation of shale gas technology is focused on three areas: reducing the environmental footprint, improving capital efficiency, and extending field life through enhanced recovery. Closed-loop water systems now recycle 90%+ of flowback water. Automated drilling systems reduce the number of rigs required while maintaining production. And pressure management strategies extend plateau production periods.

The technologies that enabled the shale revolution are still evolving. What remains constant is the need for an integrated solution that combines mechanical innovation, data analytics, and operational discipline. The rock hasn’t changed, but our ability to unlock its resources efficiently and responsibly has been completely transformed.

Related Resources

- Understanding Natural Gas Formation and Geology – Explore the geological processes that create natural gas deposits and how different reservoir types influence extraction methods. This foundational guide covers sedimentary basin development, organic matter maturation, and the unique characteristics of unconventional resources.

- Environmental Considerations in Hydraulic Fracturing – A comprehensive analysis of the environmental impacts, mitigation strategies, and regulatory frameworks governing hydraulic fracturing operations. Includes case studies on water management, methane abatement, and community engagement practices.

- The Economics of Shale Gas Development – A detailed breakdown of the capital requirements, operating costs, and economic metrics for shale gas projects. Features sensitivity analysis on commodity prices, technological improvements, and regional cost variations.