How is Natural Gas Transported?

Every winter morning, when you turn on the thermostat, natural gas—sometimes from 1,500 miles away—flows directly to your home. Behind this simple act lies one of the world’s greatest engineering feats: over three million miles of pipelines, equal to traveling to the Moon and back six times.

This vast network powers 177 million Americans’ homes, fuels industries, and generates 40% of the nation’s electricity. From Texas wellheads to Boston apartments, the journey of natural gas depends on advanced technology, multiple transport methods, and strict safety standards.

The Natural Gas Transportation System Overview

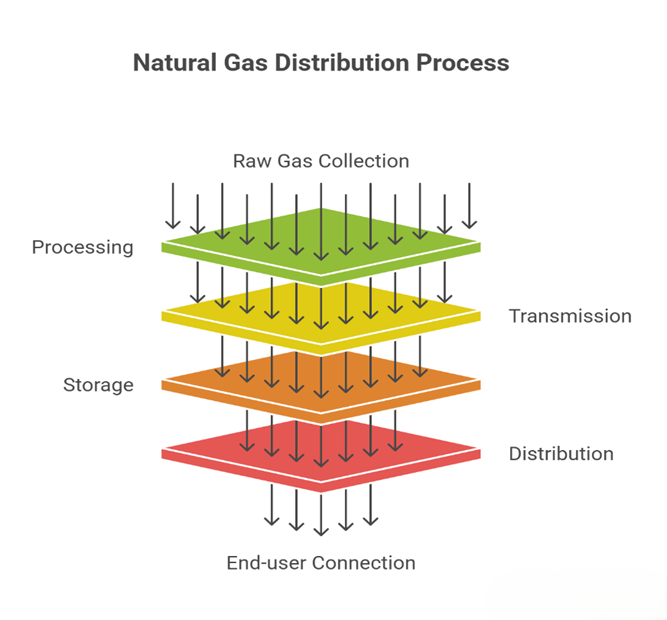

Natural gas transport runs on an efficient three-tier system that is designed for maximal efficiency and safety. In contrast to electricity, which requires immediate consumption natural gas can be stored, transported and shipped over vast distances while keeping it’s energy-content.

The transportation system consists consisting of:

Collecting system (collecting the gas that is extracted by wells)

Transmission pipelines (long-distance transport)

Distribution systems (local transportation)

The system is integrated and moves around 28.3 trillion cubic feet natural gas each year throughout the United States, with pipeline capacity increasing by 35% per year.

The current infrastructure investment is more than $7 billion per year, demonstrating the industry’s dedication to meeting the growing demand and modernizing infrastructure. The average age of pipelines is 34 years old, and numerous segments that have been upgraded with modern materials and monitoring technology.

Unlike compressed natural gas (CNG), LNG is designed for long-distance transportation and large-scale storage. Once delivered, LNG is regasified and transported via pipelines to businesses, homes, and power plants.(What Is Liquefied Natural Gas Used For)

Pipeline Transportation: The Infrastructure Backbone

Gathering and Transmission Systems

Pipeline infrastructure for natural gas starts with gathering lines that gather gas from wells in individual pipes. The smaller diameter pipes (2–8 inches) are operated at low pressures of between 200 and 800 PSI which feed more extensive transmission lines.

Transmission pipelines are part of the natural gas highway, transporting huge quantities throughout states as well as regions. The high-pressure steel pipelines (up to 1440 PSI) vary from 6 to approximately 48 inches wide with compressor stations located at every 50 to 100 miles, to ensure flow and pressure.

Distribution Networks

Local distribution companies manage the final section which reduces pressures from the transmission level to safe pressures for residential use (0.25–5 PSI). These distribution networks comprise over 2.2 million miles of service lines and mains which reach homes of individuals and businesses via sophisticated pressure control systems.

Transportation Methods Comparison

Table 1: Natural Gas Transportation Methods Analysis

| Method | Distance | Capacity Volume (BCF/day) | Typical Pressure | Infrastructure Cost |

| Gathering Lines | 5–50 miles | 0.1–10 | 200–800 PSI | $1–3M per mile |

| Transmission Pipelines | 50–2,000 miles | 50–3,500 | 600–1,440 PSI | $5–15M per mile |

| Distribution Lines | 0.1–20 miles | 0.01–50 | 0.25–60 PSI | $0.5–2M per mile |

| LNG Tankers | Unlimited | 100–180 | -260°F (liquid) | $200M per vessel |

LNG Transportation: Moving Gas Across Oceans

If pipeline transportation isn’t possible, natural gas is transported in the form of liquefied natural gas (LNG). This process involves cooling natural gas to -260°F, thereby reducing its volume to 1/600, and permitting ocean shipping.

LNG transportation starts at liquefaction facilities, in which natural gas is subjected to complex cooling processes. Specially designed LNG tankers – costing between $200 and $300 million – have double-hulled designs and advanced storage systems.

At the destination ports, LNG undergoes regasification and is injected into pipeline networks. Globally, LNG trade is averaging 350 million tons per year, with the U.S. becoming the largest LNG exporter by 2023.

The Step-by-Step Transportation Process

Delivering natural gas from wellhead to residence involves six key steps:

- Well Collection – Gathering lines capture gas produced by wells (100–400 PSI).

- Process and Treatment – Raw gas processed to remove CO₂, H₂S, and liquids.

- Transmission – High-pressure pipelines transport across states.

- Storage Integration – Underground storage holds over 4 trillion cubic feet.

- Distribution – Local companies reduce pressure for safe use.

- End-user Connection – Individual service lines with meters and safety valves.

Pipeline Infrastructure Components

Table 2: Critical Pipeline Infrastructure Systems

| Component | Function | Frequency | Safety Features |

| Compressor Stations | Maintain pressure/flow | Every 50–100 miles | Automatic shut-off, fire suppression |

| Regulation Stations | Pressure reduction | Every 10–50 miles | Pressure relief valves, emergency vents |

| Valve Stations | Flow control/isolation | Every 5–20 miles | Remote operation, fail-safe closure |

| Cathodic Protection | Prevent corrosion | Continuous | Automated monitoring |

| SCADA Systems | Remote monitoring | 24/7/365 | Leak detection, pressure monitoring |

Safety and Monitoring Technologies

Natural gas transport has a delivery security rate of >99.99%. Key technologies include:

- Acoustic monitoring & pressure wave analysis

- Satellite-based methane detection

- Intelligent pigs for pipeline inspection every 5–7 years

- Emergency shutoff devices & response units

- 24/7 SCADA monitoring systems

Economic Impact and Cost Factors

- Natural gas transportation accounts for 30–50% of residential bills.

- Typical transmission cost: $0.15–0.50 per MCF (<500 miles).

- Pipeline projects create 2,500–3,500 jobs per $1B invested.

Future Transportation Innovations

- Smart pipelines using AI for predictive maintenance.

- Hydrogen-ready infrastructure (up to 20% hydrogen blends).

- Digital twin technology for real-time modeling and disaster response.

Related Articles

Natural Gas Pipeline Safety Regulations Guide – Federal safety regulations & compliance.

Understanding Natural Gas Processing and Treatment – How gas is purified before transport.

LNG vs Pipeline Transportation Economics – Cost-benefit analysis of shipping vs pipelines.