How to Work Flare Gas Recovery System

What is a Flare Gas Recovery System?

A flare gas recovery system is an integrated solution that collects gases normally flared, processes them, and redirects them back into the plant as usable fuel or feedstock.

How Does a Flare Gas Recovery System Work?

Main Components of a Flare Gas Recovery System

| Main Components | Function |

| Knock-out drum | Removes liquids and condensates from flare gas |

| Compressors | Increase gas pressure for downstream use |

| Heat exchangers / Coolers | Reduce gas temperature before reuse |

| Seal gas system | Ensures safety and prevents backflow |

| Fuel gas system / Storage | Where recovered gas is redirected for combustion or reinjection |

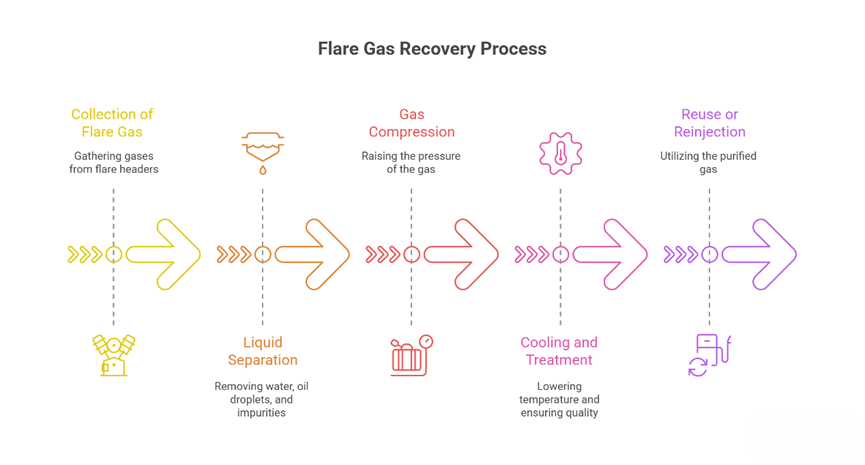

Step-by-Step Flare Gas Recovery Process

- Collection of Flare Gas – The system captures flare gases from flare headers, which would otherwise be burned off and released into the atmosphere. This step reduces waste, minimizes emissions, and recovers valuable hydrocarbons for further use.

- Liquid Separation – The collected gas passes through a knock-out drum or separator, which efficiently removes water, oil droplets, and other impurities. This ensures that the gas entering downstream processes is free from contaminants that could damage equipment or affect quality.

- Gas Compression – Compressors increase the pressure of the separated gas, making it suitable for reuse within the plant. Compression is essential for transporting the gas through pipelines and preparing it for further processing or storage.

- Cooling and Treatment – Heat exchangers lower the temperature of the gas to prevent corrosion and maintain stability. Additional treatment steps, such as filtration, dehydration, or chemical scrubbing, further ensure that the gas meets quality and safety standards.

- Reuse or Reinjection – The purified gas can be applied in multiple ways:

Fed back into the fuel gas network for power generation

Used as feedstock in petrochemical units

Re-injected into reservoirs to support enhanced oil recovery

Advantages of Flare Gas Recovery System

The benefits of installing a flare gas recovery system go beyond environmental protection:

Environmental Benefits

Lower CO₂ and methane emissions

Helps companies meet zero routine flaring initiatives set by the World Bank and other organizations

Economic Benefits

Reduces fuel costs by reusing recovered gas

Creates additional revenue by selling surplus gas

Provides a measurable ROI by cutting flaring-related penalties

Operational Benefits

Improves energy efficiency across refinery operations

Enhances corporate sustainability reporting

Strengthens community trust through responsible practices

Applications of the Flare Gas Recovery System

Flare gas recovery is widely implemented in:

| Applications | Describe |

| Oil Refineries | For fuel gas networks and steam generation |

| Petrochemical Plants | As feedstock for chemical processes |

| LNG Facilities | To maximize gas utilization and reduce carbon footprint |

| Gas Processing Plants | To optimize gas-to-liquids conversion and reduce losses |

Future Trends in Flare Gas Recovery

The future of flare gas recovery systems is closely tied to global energy transition strategies. Key trends include:

Integration with Carbon Capture and Storage (CCS) – enhancing decarbonization efforts

Digital Monitoring and Automation – using AI and IoT sensors for real-time optimization

Zero Routine Flaring by 2030 – aligned with the World Bank’s global initiative

Green Financing Incentives – governments and investors increasingly favor projects that reduce emissions

KAITIANGAS: Your Professional Partner for Flare Gas Recovery

Founded in 2002, KAITIANGAS specializes in the recovery and treatment of flare gas resources. The company focuses on the development, engineering design, and global rollout of flare gas recovery and liquefaction technologies and equipment. KAITIANGAS boasts independent intellectual property rights, proven system solutions, and a professional team. We have successfully built and operated numerous wellhead LNG recovery projects in China, the Middle East, and Southeast Asia, accumulating extensive field experience and technical expertise.

Conclusion

The flare gas recovery system is no longer just an optional upgrade — it is a critical technology for oil, gas, and petrochemical industries worldwide. By capturing and reusing gases that were once flared, companies can reduce emissions and support climate goals, cut costs by converting waste into usable fuel, and improve efficiency while meeting regulatory standards

As the energy sector moves toward sustainability, investing in a robust flare gas recovery process positions organizations for both operational efficiency and environmental responsibility.