Practical Technical Solutions to Address the Challenges of Gas Recovery in Indonesia

As a full-service provider specializing in gas recovery, liquefaction, and system integration for oil and gas, petrochemical, and industrial clients, KAITIAN GAS focuses on putting advanced technologies and engineering experience into practice: offering integrated services from feasibility studies, engineering design, EPC execution, to commissioning and maintenance support.

We realize that technology in itself is not the issue; rather, the trick lies in integrating the right technology into the client’s unique local geographical, regulatory, and market conditions to provide the required economic output in a reliable manner. This article will take up the Indonesian market as a case study and try to tackle the most common technical pain points with actionable, quantifiable solutions.

Why Customization is Needed for Indonesia

As one of the world’s major regions for associated gas emissions from oil and gas, Indonesia has made some progress in conventional flare combustion, but still faces many challenges. Therefore, Indonesia urgently needs highly customized technologies centered on system integration to address issues such as numerous point sources and dispersed small flare combustion sources, data gaps, and a fragmented downstream market.

Challenges and Solutions in Natural Gas Recovery

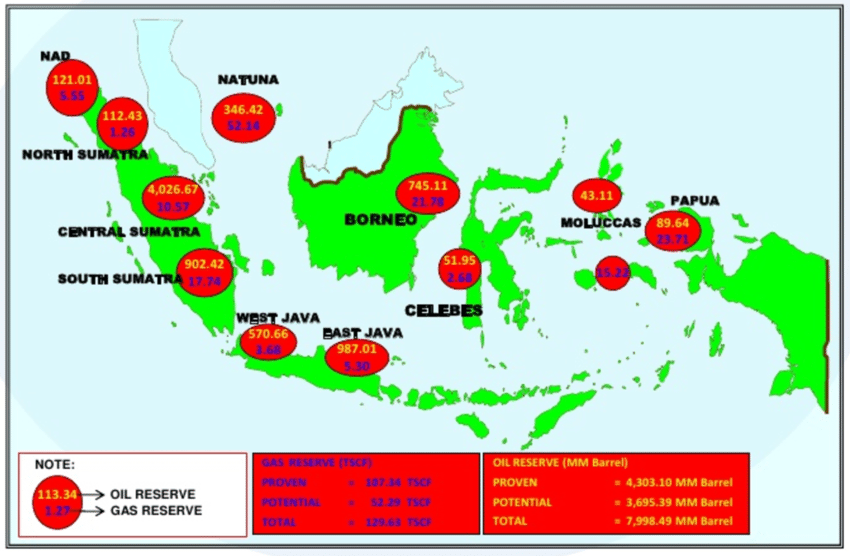

Indonesia is at a very critical juncture in its energy transition. It is one of the largest oil and gas producers in Southeast Asia, with some of the highest rates of conventional flaring emissions in the world. In the 2022 data from the World Bank’s Global Gas Flaring Reduction Partnership, for instance, it is estimated that Indonesia burns about 40 billion cubic feet of natural gas each year, which translates to releasing over 30 million tons of carbon dioxide.

KAITIAN GAS, a leading manufacturer of natural gas recovery, liquefaction, and system integration solutions with its base in China, has been closely involved in numerous projects throughout Southeast Asia and has much first-hand experience of the special technical and implementation challenges in Indonesia.

Pain Point 1: Considerable Fluctuations in Gas Flow and Composition

Most oil fields in Indonesia are dispersed, especially in East Kalimantan, Sumatra, and offshore blocks. The associated gas flow is featured by strong fluctuation, high humidity, unstable pressure, and complex composition. According to studies, with fluctuations of flow over ± 25%, the efficiency of the conventional compression systems drops by 35-50%, and this leads to more frequent startup-shutdown events, besides causing high energy consumption.

KAITIAN GAS Solution

Provides modular, variable-speed compression packages-VSD screw compressors and multi-stage compressors with intelligent control-to match turndown amplitudes exceeding 30%. Built-in flow surge protection is also available.

Smoothes fluctuations through short-term gas holder buffering and by using regional gathering and transportation strategies.

The control layer uses predictive algorithms, training models on 60–90 days of historical measurement data to advance operating points in order to avoid frequent start-ups and shutdowns and improve reliability and recovery rates.

The field-module-system integration solution can greatly improve the system’s applicability in Indonesia’s complex environment.

Pain Point 2: Equipment Corrosion and Failure Caused by Harmful Impurities

Some fields in Indonesia exhibit particularly high amounts of H₂S, CO₂, and water vapor. These “dirty gases” can be responsible for problems of compressor cavitation, heat exchanger corrosion, and catalyst deactivation. Average equipment lifetime is reduced by a factor of 40% in systems without desulfurization pretreatment.

KAITIAN GAS Solution

A pre-treatment skid (gas conditioning module) integrated during the design phase of the system, with dehydration (molecular sieve or glycol), desulfurization (amine tower/adsorption bed), and liquid separator.

Applying anticorrosion materials, like duplex stainless steel, and protective coatings for extended equipment life.

Modular design of replacement parts allows easy and quick maintenance on site.

Making the conditioning module a standard system component, our clients significantly reduce lifecycle maintenance costs by meeting the reliable operation requirements of the Indonesian oil and gas industry.

Pain Point 3: Poor Measurement Baseline and Insufficient Data Transparency

Many oil fields in Indonesia lack continuous gas flow and composition monitoring, often resulting in a “lack of data support” dilemma in the project feasibility studies and carbon credit application stages. Orisaremi, Energy Policy, 2021, said data gaps were among the key factors contributing to the high failure rate of FGR projects in developing countries.

KAITIAN GAS Solution

Deploy an MVP measurement package (60–90 days): Portable ultrasonic flowmeter + short-term on-site gas chromatography sampling to establish real-world operating condition databases.

Establish an IoT + satellite double verification mechanism: First, access the ground-based metering data into the cloud platform, then perform satellite (VIIRS/Sentinel) field verification.

Introduce data governance and tamper-proof recording mechanisms, such as timestamping and encrypted signatures, to lay the foundation for future carbon credit and compliance audits.

This can enhance access to Indonesian projects in the regulatory/carbon market and increase their attractiveness for investment.

Pain Point 4: Small and Dispersed Fields Make Economies of Scale Difficult

More than 60% of Indonesia’s oil and gas blocks are mature, low-production oil fields; daily combustion is mostly less than 1 MMSCF. Building a separate fixed system requires too much investment and is not economically viable.

KAITIAN GAS Solutions

Building Cluster Hubs: Connect several small wells/fields in the neighborhood by pipeline network to a single medium-sized FGR system.

Providing Mobile/Leasing FGRUs: Suitable for sites with low or fluctuating production, reducing capital expenditure per site.

By leveraging our “system integration + flexible solutions” capabilities, optimal scale for Indonesia’s decentralized structure can be designed.

The model not only enhances economics but also facilitates rapid deployment for Indonesian oil and gas companies in more dispersed areas.

Pain Point 5: Weak On-Site Maintenance Capabilities and Harsh Environment

Indonesia is indeed located in a region of high temperature, humidity, and coastal salt spray, all factors that place great demands on equipment reliability, maintenance cycles, and the technical skills of personnel.

KAITIAN GAS Solutions

All Modular Systems are Tropically Designed: Includes NEMA 4X protection, a tropical cooling system, and a moisture-proof control cabinet.

Local Training and Remote Expert Support: Providing module installation and maintenance training with local Indonesian technical colleges and reducing fault response times with remote diagnostics/AR maintenance tools.

We offer a full system approach of “one-time delivery and long-term operation/maintenance support”, including design, manufacturing, installation, commissioning, operation/maintenance training, and remote support.This design significantly improves the reliability of projects in Indonesia, reduces O&M costs, and is in line with the local government’s direction to promote the construction of a localized operation and maintenance system.

Commercial Implementation Roadmap

| Phase | Timeframe | Main Objective | Key Tasks |

| Phase 1: Preparation | 0 – 1 month | Project initiation and preliminary communication | – Quick policy/market scan- Sign NDA and conduct initial client visit- Define project scope and data requirements |

| Phase 2: Data Measurement & Feasibility | 1 – 3 months | Obtain real operational data and establish design basis | – Deploy MVP measurement package (60–90 days)- Collect flow and composition data- Develop preliminary feasibility and economic model |

| Phase 3: System Design & Solution Finalization | 3 – 6 months | Complete system engineering design and business model | – Design pre-treatment, compression, collection/liquefaction modules- Deliver CAPEX/OPEX model- Draft cooperation model (EPC, ESA, JV, etc.) |

| Phase 4: Implementation & Training | 6 – 12 months | System delivery and on-site commissioning | – Equipment procurement and modular installation- On-site commissioning and startup- Conduct local O&M training and initial operational monitoring |

| Phase 5: Optimization & Expansion | 12+ months | Improve performance and scale replication | – Analyze operational data and optimize system- Apply for and verify carbon credits- Replicate model across regional or cluster projects |

How KAITIAN GAS Helps the Implementation of Natural Gas Recovery Projects

Indonesian clientele have different needs, and KAITIAN GAS provides a range of various flexible cooperation models:

Investment & EPC Model

Financially supports the project and engages in the entire project execution chain from initiation to delivery-a one-stop shop, so to say.

Joint Venture & Co-operation Model

We can co-invest and co-operate projects with local Indonesian companies and share a long-term profit.

Technology Licensing & Equity Participation Model

It offers licenses for core recovery technologies and takes part in the equity of projects to enjoy project profits.

EPC Turnkey Model

We undertake design, procurement, construction, commissioning, and delivery in turnkey contract form.

Technical Consulting Model

Focuses on market assessment, technical planning, and feasibility studies suitable for clients who would want to begin the scheme evaluation phase first.

Customized Models

Innovative models like BOT, BOO, and carbon asset cooperation can be flexibly adjusted according to the specific Indonesian project.Through these diversified cooperation models, we can substantially reduce the threshold for project entry in Indonesia, share risks, and accelerate implementation.

Conclusion and Invitation

Although funding is manageable, business models are innovative, and the technology is available domestically, “it is a question of how to integrate these elements and deliver a system that can operate stably in the long term in a hot and humid tropical environment.” As a Chinese service provider with comprehensive delivery capabilities in natural gas recovery, liquefaction, and system integration, KAITIAN GAS is ready to offer services ranging from measurement and modeling → modular equipment → system integration delivery → localized operation and maintenance training → carbon credit verification.

If you would like us to provide:

A) A 60–90 day measurement and feasibility report; or

(B) a draft investment and financing and ESA model for a province/oil field in Indonesia,

please get in touch with us. After site receipt and tentative data, we can give a technical tender along with a budget estimate within 7 working days.

References

- Gai, H. (2020). Clean combustion and flare minimization to reduce greenhouse gas emissions. Energy Reports.

- Orisaremi, K.K. et al. (2021). Potential reductions in global gas flaring for determining decarbonization pathways. Energy Policy.

- Tahmasebzadehbaie, M. (2024). Optimized flare gas recovery technology with consideration of LCA and reliability. Journal of Petroleum Science and Engineering.

- Comprehensive Review (2024). Reliable sustainable management strategies for flare gas recovery — technical, environmental modeling and economic assessment. Energy Conversion & Management.

- Taha, A. (2024). The impact of a zero-flaring system on gas plants. Journal of Engineering Applied Sciences.

- World Bank / GGFR (2022). Indonesia Country Flaring Data Profile.