KAITIAN GAS Stranded Natural Gas Recovery Solutions

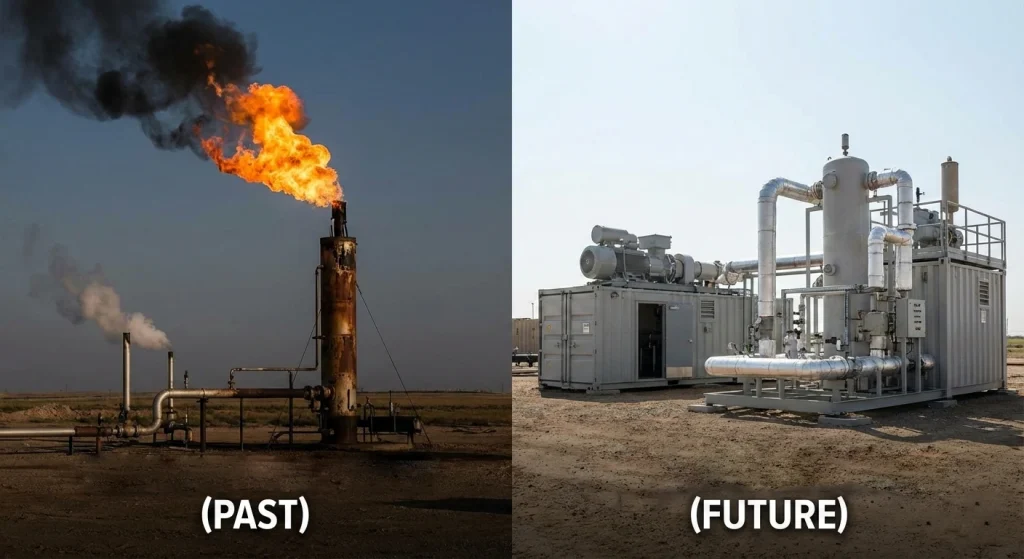

During oil and gas development, operators flare or vent stranded natural gas because of its scattered distribution and absence of pipeline infrastructure and lack of economic viability. The energy waste creates economic losses while increasing greenhouse gas emissions which harm companies’ environmental, social, and governance performance and their commitment to global carbon reduction goals. Systematic recovery solutions enable the conversion of stranded natural gas into energy carriers which create both economic and environmental advantages. KAITIAN GAS offers businesses complete recovery solutions which follow systematic procedures.

What is Stranded Natural Gas?

Stranded natural gas refers to natural gas resources that, due to geographical, economic, or infrastructure limitations, cannot be transported to market through traditional pipelines during oil and gas exploration and production. Natural gas of this type exists in remote oil fields which lack access to surface infrastructure and in gas fields which exist outside of developed areas and in gas fields which produce gas alongside oil extraction. The resources remain idle in their “stranded” state because their physical recovery is possible but their use remains blocked by economic and logistical and technological difficulties.

The main types of stranded natural gas include: associated gas, non-associated gas, gas from isolated fields, and gas from low-producing or dispersed sources. Theoretical research establishes these gases as energy resources which can generate liquefied natural gas and power generation for industrial operations and on-site power generation. The process of flaring or venting gases that are not recovered results in large quantities of CH₄ and CO₂ emissions and leads to both energy waste and economic losses.

The process of recovering stranded natural gas requires technical solutions to solve energy transition problems while energy companies need this technology for their operational efficiency and investment-building and sustainable development goals.

Core Steps of a Systematic Recovery Solution

A complete stranded natural gas recovery project typically includes the following stages, covering the entire process from initial assessment to system commissioning:

Feasibility Consulting and Assessment for Retained Natural Gas Recovery Project

The project requires a feasibility study through its initiation stage because it needs this assessment to provide scientific validation for its design and investment process. The phase starts with stakeholders evaluating natural gas resource quantities and production potential. The stakeholders need to analyze the gas composition and volatility and processing challenges before they can compare different technological processes which include compression and dehydration and purification and liquefaction. The project needs a complete economic viability study together with its environmental impact assessment. The company uses this detailed analysis to support its decision-making process because it ensures proper investment returns while meeting all applicable laws and environmental standards.

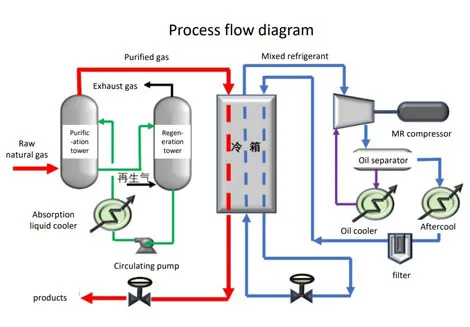

Engineering Design and Process Integration

The project proceeds to its engineering design and process integration stage after the completion of its feasibility evaluation. The project team will develop a specific process design which includes gas dehydration and purification and compression and cooling based on the natural gas characteristics and environmental conditions found at the site. The design process requires two systems which will control pressure and operational processes to maintain gas stability while it is used in future applications. The project implementation process requires modular and containerized design because it facilitates construction work at the site and reduces project completion time while standardizing system components and making them easier to maintain.

EPC Execution and On-Site Construction

The EPC execution phase serves as the essential process which converts the design solution into an operational system. This phase includes equipment procurement and manufacturing, on-site installation and commissioning, as well as construction management and safety control. The engineering team must strictly adhere to design requirements during construction, ensuring the correct installation of each unit module and conducting system integration and pre-operation checks. The retained natural gas recovery system must achieve operational readiness through this phase which maintains safety standards and operational efficiency and project quality.

Commissioning and Continuous Optimization

The active operation of the system starts after its official launch into service. The process needs equipment to be first installed and then tested for its operational capabilities while the system requires integration of remote monitoring tools and data acquisition systems to enable continuous tracking of all pressure and flow and gas quality metrics. The establishment of maintenance protocols together with staff education programs guarantees that the system will operate reliably throughout its entire lifespan while data examination will help refine operational standards to enhance gas recovery results. The current stage of the project establishes two benefits which include stable production capacity and essential information for upcoming expansion and technology development.

Core Technologies of Recycling Systems

Modular and Integrated Design

The system uses a skid-mounted system to combine essential modules which include compression and cooling and control systems. The system will decrease the need for on-site construction work while bringing down installation space requirements and increasing system deployment options.

Compression, Dehydration, and Purification Technology Chain

The gas from wells and associated gas contains complex chemical components, which include water and sulfur, that make it difficult to process through downstream treatment methods. The process requires effective water removal and acid extraction together with carbon dioxide elimination to prepare for subsequent compression and utilization operations.

Intelligent Control and Remote Monitoring

By integrating an intelligent control platform and data analysis system, the on-site system can achieve:

- Real-time operational status monitoring;

- Remote parameter adjustment;

- Implementation of preventative maintenance plans.

Intelligent features improve system stability and operational efficiency.

Comparison of Technical Pathways for Stranded Natural Gas Recovery

| Technical Pathway | Advantages | Limitations | Applicable Scenarios |

| Small-Scale LNG Plant | Enables liquefaction and transportation; expands market access | High capital investment | Remote oilfields; stable volumes of associated gas |

| GTU + LNG | Highly adaptable to gas streams with high CO₂ / H₂S content | Complex system; higher operation and maintenance costs | High-sulfur or high-acid gas sources; LNG export-oriented projects |

| Onsite Power Generation (Gas-to-Power) | Fast deployment; improves energy self-sufficiency | No long-term energy storage | Remote or off-grid oilfields |

| Industrial Fuel Use (Gas-to-Heat) | Direct industrial consumption; reduces emissions | Requires proximity to end users | Industrial facilities or drilling sites near oilfields |

From Waste to Value

The ongoing worldwide movement towards better energy efficiency and decreased carbon emissions requires oil and gas companies to adopt stranded natural gas recovery methods because these methods have become essential for maintaining their competitive edge and achieving sustainable development goals.Through systematic engineering solutions energy resources can be transformed from their current state as waste materials into active resources that create clean energy products from previously unused energy sources.

For customized stranded natural gas recovery solutions for specific oilfields contact KAITIAN GAS. We provide complete technical service solutions which begin with consulting and design and continue through construction and operational support to ensure complete implementation of technology and successful project outcomes.