coalbed methane Recovery & Extraction

Coalbed methane (CBM) is widely present in both unmined and active coal seams, often existing in the form of gas with characteristics such as low pressure, high methane concentration, and significant production fluctuations. Due to dispersed well layouts, high water content, and complex impurity compositions, CBM and mine gas are frequently vented or flared during extraction, leading to resource wastage and emission pressures, severely impacting mine safety and environmental compliance.

With increasingly stringent requirements for mine safety, clean energy development, and emission reduction, efficient recovery of CBM and mine gas has become a critical focus in unconventional gas management, necessitating modular, standardized, and engineered solutions tailored to on-site conditions.

Solution Approach

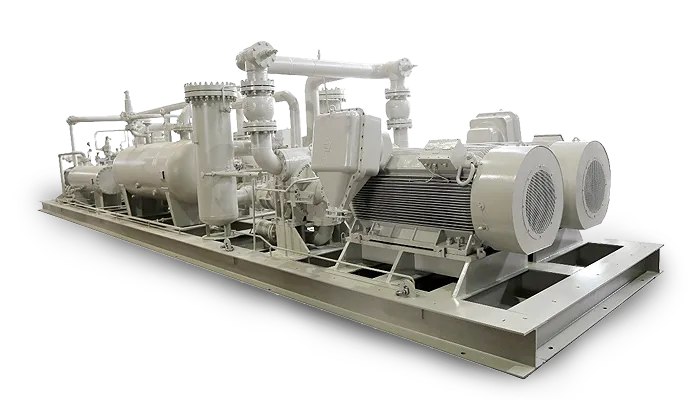

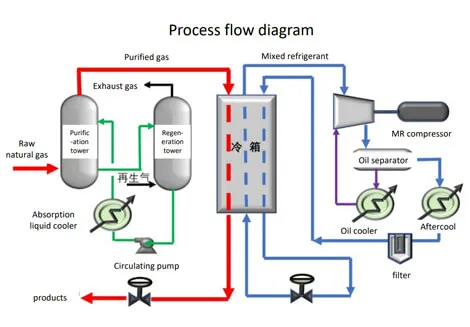

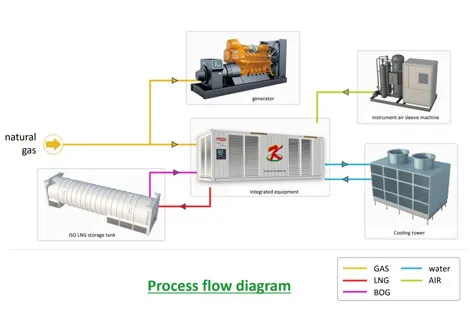

KAITIANGAS addresses the high water content, high corrosiveness, and significant volatility characteristics of CBM and mine gas by developing skid-mounted, highly integrated, and intelligent recovery systems tailored to the actual deployment needs of coal mine stations. We offer comprehensive professional services encompassing project consulting, engineering design, equipment manufacturing, EPC execution, and system commissioning, supporting the safe and efficient recovery and centralized processing of multi-well gas sources in mining areas.

Comprehensive Solution

Technical Equipment Highlights

Skid-mounted CBM processing units, mine gas dehydration and compression modules, modular system structures, small footprint with rapid deployment, design resistant to high humidity and corrosion, explosion-proof certification standards, remote monitoring systems, data acquisition and analysis platforms, support for multi-well gas source grid integration, automatic control platforms, flexible expansion capabilities, and adaptability to high-altitude and low-temperature mining environments.

Application Scenarios

Applicable to CBM extraction stations, mine gas processing stations, centralized gas recovery points at underground and wellhead locations, multi-well combined stations, clean gas supply stations in remote mining areas, mine gas emission control points, unconventional gas field clean development blocks, supporting gas source stations for coal mine extraction systems, and energy coupling projects in mining areas.

Customer Value Proposition

Efficient recovery of CBM and mine gas resources significantly reduces emission intensity and safety hazards; flexible deployment of skid-mounted systems with compact footprints, automated operation, and remote control reduces labor pressure; support for multi-station replication and regional promotion enhances system operational stability and economic returns, providing strong assurance for safe, clean, and compliant operations in coal mining blocks.