Industrial Off-Gas Recovery

During industrial production, waste gases such as coke oven gas and ammonia synthesis tail gas contain significant recoverable components and calorific value. Without proper treatment, they are often directly emitted, resulting in resource waste and environmental pollution. Due to the complex composition, high volatility, and variable site conditions of these gases, traditional treatment methods often fail to meet both environmental and economic goals.

With the ongoing push for green industrial transformation and stricter emission standards, there is an urgent need for systematic and integrated off-gas recovery solutions that enable efficient separation, purification, and conversion of gas components, promoting resource recycling and regulatory compliance.

Solution Approach

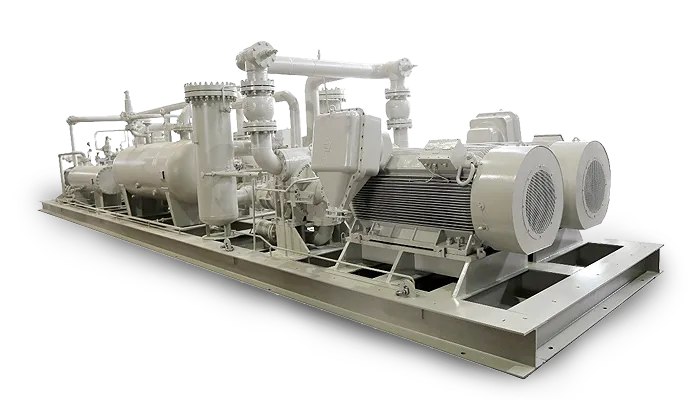

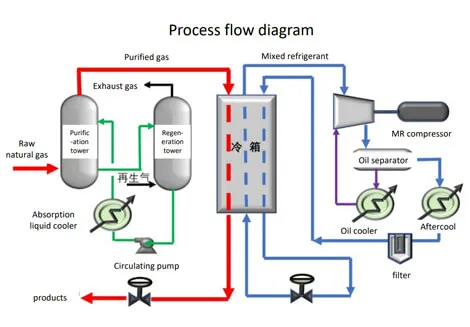

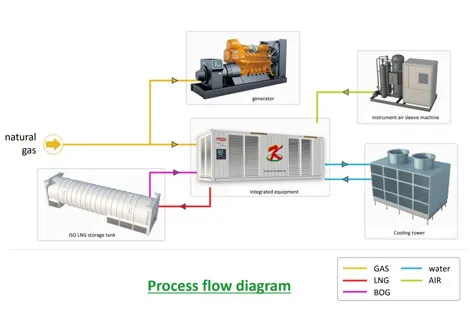

KAITIANGAS, based on an in-depth understanding of coke oven gas and ammonia synthesis tail gas characteristics, designs modular skid-mounted off-gas recovery systems tailored to industrial site conditions, covering the full process of gas collection, desulfurization, ammonia removal, purification, and compression. We offer integrated services across project consulting, process design, EPC project execution, commissioning, and operation & maintenance to ensure stable and efficient system performance.

Comprehensive Solution

Technical Equipment Highlights

Modular skid-mounted design, compact footprint, use of corrosion-resistant and explosion-proof materials, high-efficiency desulfurization and ammonia removal technologies, integrated intelligent control systems, remote monitoring and data analytics support, rapid assembly and flexible expansion capabilities to suit variable industrial environments.

Application Scenarios

Applicable to industrial enterprises such as coking plants and ammonia synthesis facilities for off-gas collection and treatment, especially suitable for sites with limited space, complex gas compositions, and strict emission requirements, supporting both centralized treatment in industrial parks and customized solutions for standalone units.

Customer Value Proposition

Through systematic recovery and purification of industrial off-gases, clients significantly reduce emission pressures, improve gas resource conversion rates, enhance compliance capabilities, lower maintenance difficulty and operational costs, and achieve both environmental and economic benefits.