Offshore Oilfield Associated Gas Recovery

During offshore oilfield development, large volumes of associated gas, wellhead gas, and flare gas are generated. Due to limited platform space, complex environmental conditions, and high operation and maintenance difficulty, these scattered gas resources are often directly vented or flared, leading to serious resource waste and carbon emission issues, while also affecting platform operation efficiency and environmental compliance.

As demands for greener and more standardized offshore oil and gas development continue to rise, the industry urgently requires systematic recovery and treatment solutions tailored to complex working conditions and high-risk scenarios, in order to achieve effective gas recovery, emission reduction, and regulatory compliance.

Solution Approach

KAITIANGAS focuses on the characteristics of high fluctuation and high corrosiveness of scattered gas sources such as associated gas and wellhead gas on offshore platforms, and builds skid-mounted gas recovery and treatment systems suited to platform conditions. We provide full-process technical services ranging from early-stage consulting, engineering design, and module fabrication to EPC execution and remote commissioning, meeting the requirements for high reliability, compactness, and explosion-proof operation on platforms.

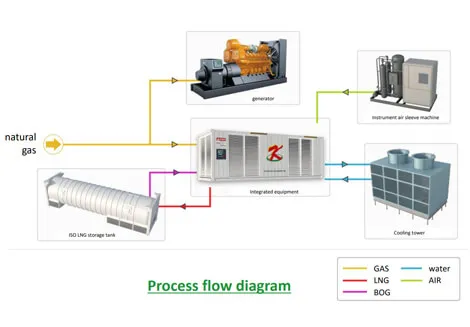

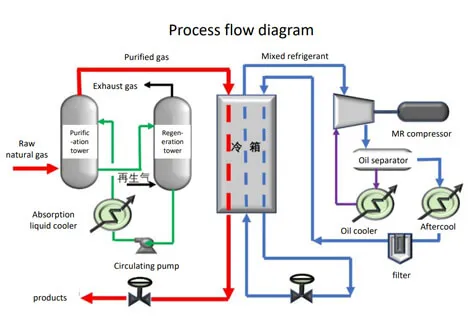

Comprehensive Solution

Technical Equipment Highlights

Skid-mounted liquefaction and compression modules, compact and lightweight design, anti-seismic and anti-corrosion structures, explosion-proof certification, remote diagnostic and operation monitoring systems, embedded control systems, fast assembly and modular combination capabilities, dual-interface deployment support for both platform and marine vessels, and adaptation to high-salt and high-humidity environments.

Application Scenarios

This solution is widely applicable to the recovery needs of associated gas, wellhead gas, and flare gas generated during offshore oilfield development. It is particularly suitable for fixed platforms, floating platforms, and remote offshore well sites. Under conditions with limited platform space, high gas source fluctuation, and limited maintenance resources, the skid-mounted modules enable rapid deployment and flexible adaptation, facilitating efficient gas collection and treatment. The system can also function as a front-end treatment unit for platform flare emission reduction, or be integrated into emergency gas recovery pathways, enhancing the platform’s overall environmental performance and operational flexibility, and meeting the needs for gas resource recovery across various scenarios and working conditions.

Customer Value Proposition

By establishing platform-specific skid-mounted gas recovery systems, customers can significantly reduce flare emissions and meet increasingly stringent environmental compliance standards, while avoiding resource waste and regulatory risks due to gas emissions. The systems are compact, occupy minimal space, and feature a high degree of automation, supporting remote operation and intelligent monitoring, which greatly reduces the workload of on-site personnel and improves overall safety management.