Onshore Oilfield Associated Gas Recovery

During onshore oilfield development, scattered gas resources such as associated gas, wellhead gas, oilfield gas, and flare gas are often vented or flared due to dispersed distribution, high recovery technical barriers, and poor economic viability—resulting in substantial energy waste and carbon emissions.

With increasingly stringent environmental regulations and rising demands for resource efficiency, oil and gas enterprises urgently require systematic solutions for gas recovery and conversion.

Our Approach

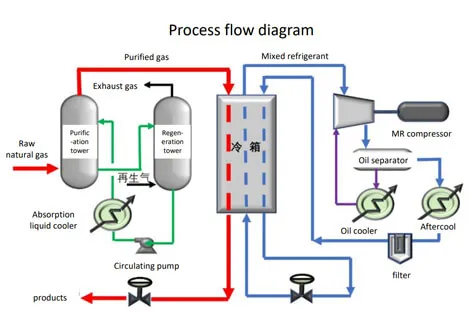

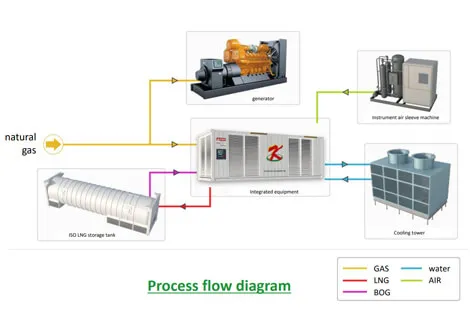

KAITIANGAS focuses on the effective collection and systematic treatment of scattered gas resources. For associated gas recovery in onshore oilfields, we provide end-to-end professional services—from feasibility consulting, engineering design, and EPC execution to system commissioning and operational support. By adopting skid-mounted system designs and customized process integration, we help clients safely and efficiently convert dispersed gas sources into clean energy for regional use.

Integrated Solution

Technical Equipment Highlights

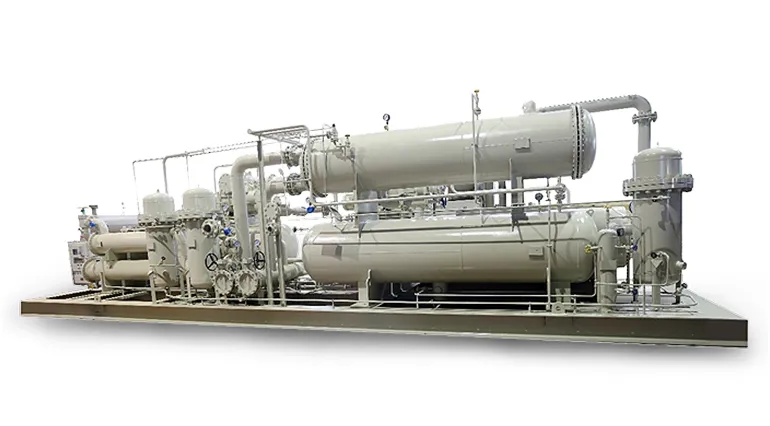

The entire recovery system is built on highly integrated units, including skid-mounted liquefaction modules, compression and cooling systems, and intelligent control platforms. The compact design minimizes footprint, simplifies transportation, and allows fast on-site assembly. Integrated remote monitoring and data analytics features improve operational efficiency and simplify maintenance.

Application Scenarios

This solution is ideal for centralized recovery of associated gas, wellhead gas, and flare gas in various onshore oilfield settings. It is especially suited for field well stations and remote oil areas, and can also serve as a front-end gas treatment unit for clean energy supply stations. The solution is particularly effective for projects targeting regional energy supply, flare emission reduction, and oil-gas integrated development.

Customer Value Proposition

By establishing a flexible and efficient associated gas recovery system, clients can significantly improve resource conversion efficiency, reduce carbon emission risks, and ensure environmental compliance. The skid-mounted system’s flexible deployment and ease of maintenance lower operational costs and enhance overall project returns.