Shale Gas Liquefaction

Shale gas resources are widely distributed in low-permeability, tight formations. The extraction process is characterized by high pressure, high water content, and high impurity levels. Due to scattered distribution, production fluctuations, and lack of infrastructure, resource development efficiency is low, leading to gas venting and non-compliant emissions, which hinder the clean and efficient transformation of shale gas.

With the accelerated development of unconventional natural gas, shale gas liquefaction has become a key pathway to enhance resource commercialization and storage and transportation flexibility. There is an urgent need for modular, standardized, and rapidly deployable technical equipment and systematic solutions.

Solution Approach

KAITIANGAS, addressing the complex composition, frequent fluctuations, and dispersed distribution of shale gas, has developed a mobile shale gas liquefaction solution suitable for wellsite conditions. This solution offers comprehensive services covering resource assessment, technical pathway demonstration, process design, skid-mounted equipment manufacturing, EPC execution, and system commissioning. It assists clients in efficiently achieving integrated processing of shale gas recovery, impurity removal, and liquefaction, supporting various scenarios such as regional natural gas peak shaving, storage and transportation, and distributed energy supply.

Comprehensive Solution

Technical Equipment Highlights

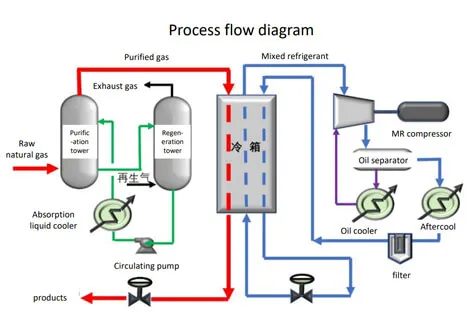

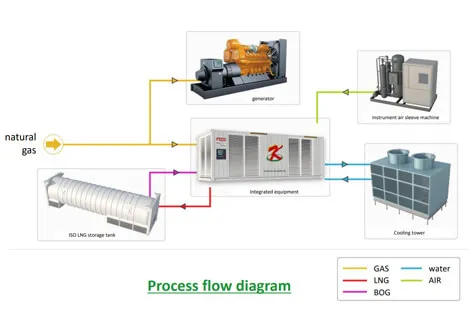

Modular skid-mounted liquefaction system with high integration, designed to operate in low-temperature environments, featuring rapid deployment and dismantling capabilities, low energy consumption with efficient liquefaction pathways, embedded intelligent control systems with high automation levels, compatibility with wellsite independent power supply and remote control, compact structure facilitating transportation and deployment, closed-loop system encompassing the entire liquefaction and storage process, support for multi-gas source mixed liquefaction with flexible adjustment capabilities, and remote operation and maintenance support with intelligent alarm systems.

Application Scenarios

Applicable to various shale gas extraction regions, particularly suitable for wellsite deployments with high initial production and significant later-stage fluctuations, scenarios lacking centralized pipeline access requiring on-site liquefaction and subsequent transportation, development of unconventional gas fields, distributed LNG supply stations, regional natural gas peak shaving projects, industrial park independent gas supply systems, front-end processing units for shale gas compression stations, and LNG satellite station gas supply scenarios.

Customer Value Proposition

By deploying mobile skid-mounted liquefaction units, clients can rapidly achieve on-site shale gas liquefaction and cold liquid transportation, effectively addressing development challenges posed by production fluctuations and dispersed geography. The system supports rapid deployment and modular expansion, suitable for replication across multiple wellsites, enhancing resource conversion efficiency. Intelligent operation reduces reliance on manual intervention, ensuring convenient and reliable operation and maintenance. Through the production of commercial LNG, clients can monetize gas resources and achieve economic returns, meeting objectives for clean energy transformation and carbon emission reduction.