What Specialized Equipment and Pre-Treatment Methods Are Necessary for Efficiently Recovering High-H₂S (Sour) Flare Gas?

Uncaptured and flared gas continues to propel emissions and waste that oil and gas operators must tackle to remain revenue positive.

The challenge becomes intensified when flare gas comprises a considerable amount of hydrogen sulfide (H2S), commonly known as sour gas.

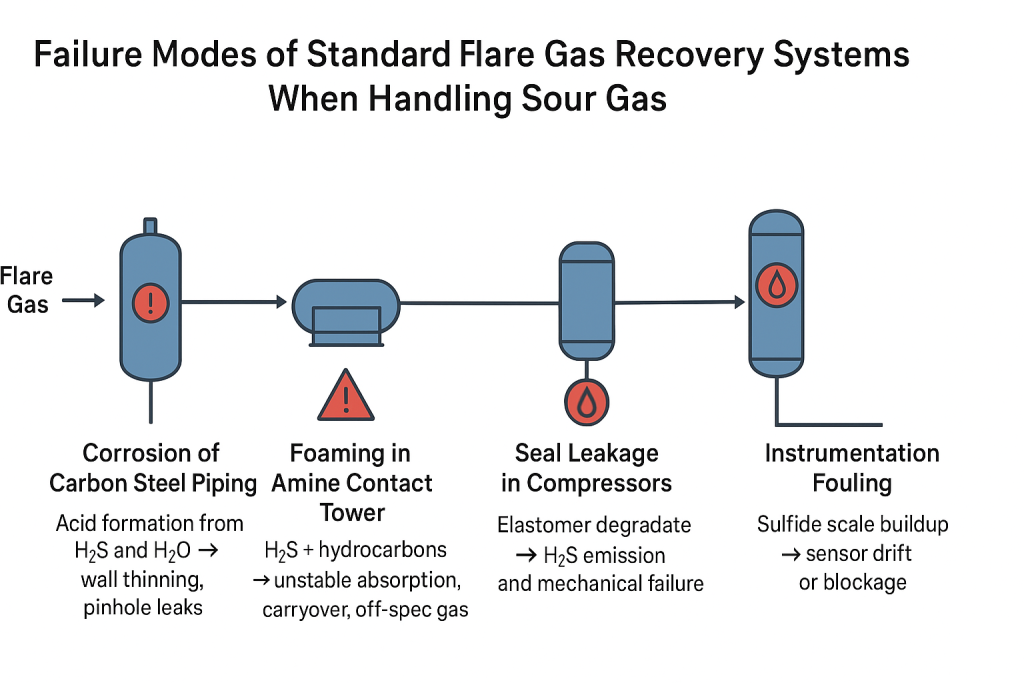

Regular flare gas recovery units (FGRUs) quickly fail due to corrosion, foaming, and toxicity hazards.

So the real question for process and project engineers is not just “Can we recover sour flare gas?” but rather:

- What specialized equipment do we need?

- Which pre-treatment methods are mandatory?

- How can we design a safe, reliable, and cost-efficient recovery system?

Why High-H₂S Flare Gas Is Different?

A considerable portion of flare gas is composed of 1–20% H₂S, which is then categorized as sour and is occasionally found in even more concentrated amounts.

Alongside these quantities of sour gas, it becomes carvinous, mystifyingly and gravely poisonous. It can kill within minutes with exposure above 700 ppm.

- Material Corrosion: Stress cracking and H₂S weld/seal sulfide attacks.

- Safety and Toxicity: Even minor leaks warrant full shutdown and evacuation protocols.

- Process Instability: Amine foaming, failed compressor seals, and erratic flare mixes.

For gas compression, a separate pre-treatment H₂S strategy is crucial. Exceeding 2-5% of H₂S in gas, it is impossible to directly compress or burn without prior conditioning.

What professional equipment is needed to recover high-hydrogen-sulfide (acidic) flare gas?

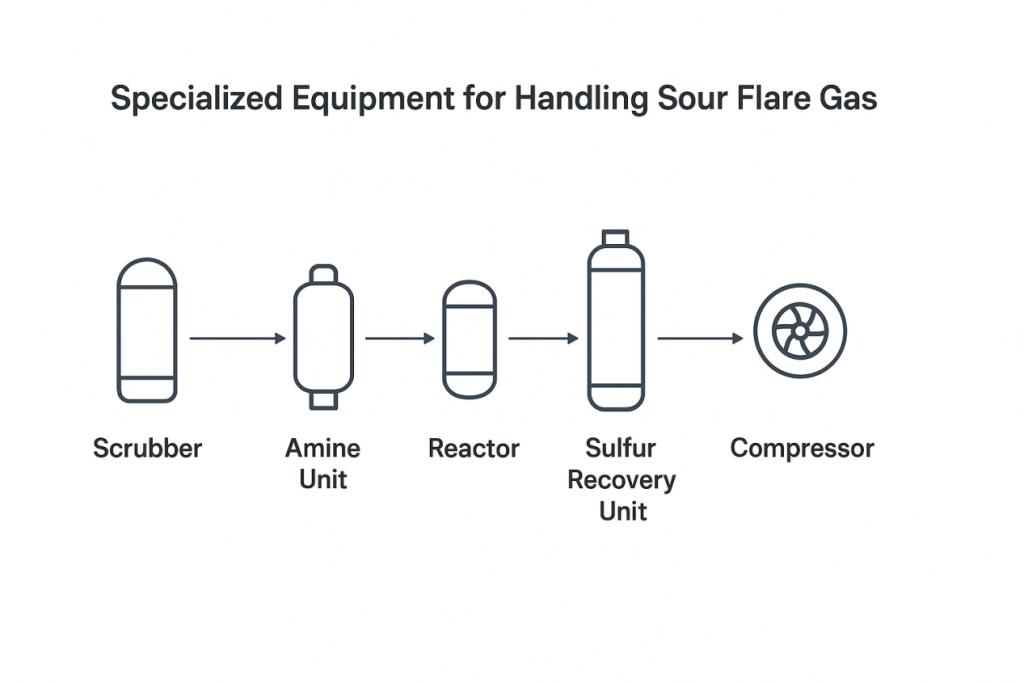

Recovering sour gas isn’t as simple as just adding an amine tower; it entails a complete redesign of the flare gas recovery chain.

Highlighted below is a non-exhaustive list of the bespoke equipment that accompanies a standard sweet gas flare gas recovery unit.

| System Section | Specialized Equipment | Main Function | Critical Design Notes |

| 1. Inlet Section | Knockout drum, flame arrestor | Remove liquids and prevent flashback | SS316L or Duplex stainless steel, NACE-rated internals |

| 2. Compression Stage | Sour gas reciprocating/screw compressor (API 618/619) | Compress gas for processing | Dual mechanical seals, nitrogen barrier, gas-tight housing |

| 3. Acid Gas Removal (AGR) | Amine absorber + regenerator / Membrane module | Remove H₂S and CO₂ | Internal coatings (phenolic or epoxy), corrosion-resistant trays |

| 4. Gas Dehydration | TEG contactor or molecular sieve | Dry the gas before reuse | Water < 7 lb/MMscf, SS304L internals |

| 5. Sulfur Recovery | Mini-Claus or chemical scavenger system | Convert or capture H₂S | For >0.5% H₂S, required by emission codes |

| 6. Safety & Venting | H₂S gas detectors, scrubbers, emergency flare | Protect personnel and environment | Redundant detection loops, fail-safe venting |

Design Tip:

Every lapping surface along with every pressure boundary must conform to NACE MR0175 / ISO 15156 to avoid sulfide stress cracking (SSC). Elastomers should be resistant to H₂S (e.g., FFKM, Aflas).

Recovery of High-Hydrogen-Sulfide (Acidic) Flare Gas – Pre-Treatment Method and Step-by-Step Process Roadmap

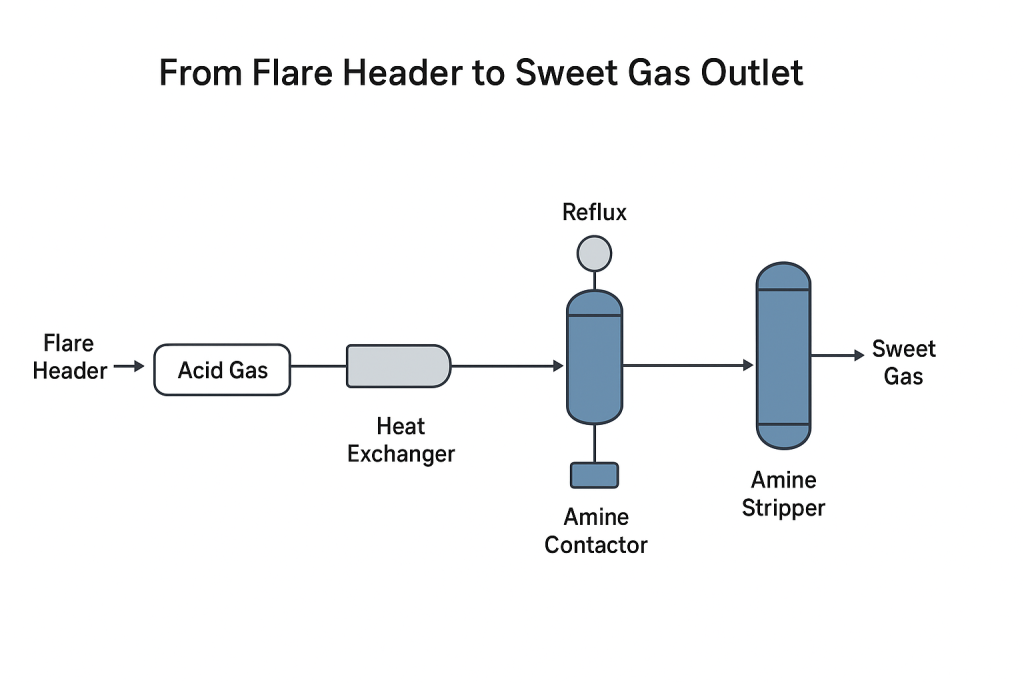

The optimum recovery procedure hinges on the degree of integration within the prep-treatment process blocks.

The following illustration summarizes the most prominent steps in the process leading up to the reuse of or reinjection of flare gasses.

Typical Pre-Treatment Sequence

1. Gas separation (knockout drum) : Removes condensate, oil mist, and particles which can be harmful to equipment downstream.

2. Compression (Low-stage) : Compresses gas to the required AGR system pressure, which can be from 5–10 bar.

Must be H₂S rated and gas-tight.

3. Acid Gas Removal (AGR)

Removal of H2S gas and processing sour gas is the core of the technology. The selection is based on the gas composition and flow rate.

- Amine systems (DEA, MDEA): Most common for high flow rates; proven efficiency >99.5%.

- Membrane separation: Modular, compact, good for remote sites or low-flow applications.

- Solid sorbents (ZnO, Fe₂O₃): Ideal for polishing or small systems.

- Caustic or chemical scavengers: Quick-deploy options for temporary treatment.

- Dehydration (TEG or Molecular Sieve): Takes out leftover water so no hydrates can form during compression or cooling.

- Sulfur Recovery or Disposal: Elemental sulfur is produced (Claus process) from H2S gas or is neutralized by liquid oxidizers or solid media.

- Final Compression & Utilization: The available vapor is to be used for power generation, reinjection or internal plant fuel gas.

Choosing the Right H₂S Removal Technology

| Condition | Best-Suited Technology | Why It Works |

| H₂S < 1% | Membrane or caustic wash | Compact and simple |

| 1–10% H₂S | Amine system (MDEA) | Economical and robust |

| >10% H₂S | Amine + Claus + Tail Gas Unit | Industrial-scale sour gas route |

| Small or remote site | Solid scavenger + membrane | Modular and low maintenance |

- Amine systems dominate large-scale recovery due to flexibility and regeneration capability.

- Membranes suit space-limited or unmanned installations.

- Solid scavengers provide a quick-start or backup solution but require frequent replacement.

Safety, Materials, and Reliability Considerations

H₂S is lethal, corrosive, and unpredictable — design must assume zero-tolerance for leaks.

Golden Rules for Sour Gas Systems:

- The material i used was NACE approved carbon steel, duplex steel, And in specially high Concentrations, 316L or Inconel.

- The design of the seal contains double mechanical seals, an inert buffer gas, continuous monitoring of the gas leaks.”

- The instruments used include automatic venting to scrubbing valves, as well as redundant H₂S detectors and isolation valves.

- The safety features included are H₂S Emergency Shutdown systems (ESD) and in designated zones, escape hoods.

Cost implications

Compared to sweet gas systems, sour gas recovery costs are typically 1.5–3× higher due to:

- Special metallurgy and coatings

- Higher maintenance frequency

- Energy-intensive amine regeneration

Real-World Implementations and Solution Providers

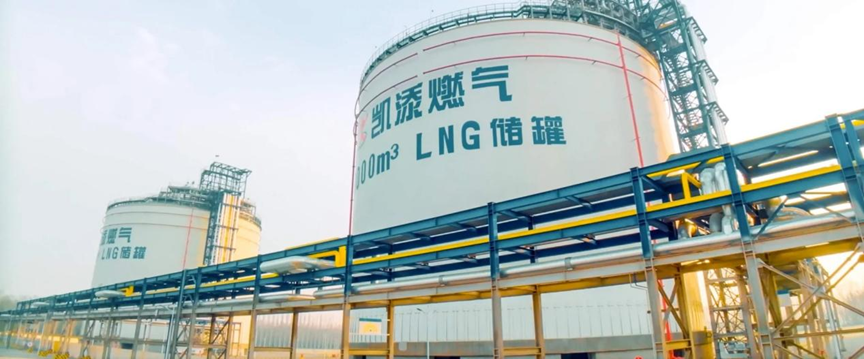

Modern suppliers like KAITIAN Gas and other process integrators now offer modular sour gas recovery packages, integrating:

- Sour gas compression

- Amine sweetening

- Dehydration

- H₂S detection and safety systems

These compact, skid-mounted systems are designed to meet API and NACE standards, enabling operators to recover >90% of flare gas even under high-H₂S conditions — while reducing emissions and improving energy reuse.

Conclusion

Recovering high-H₂S flare gas isn’t impossible — it’s a matter of engineering discipline and system integration.

Owing to the right pre-removal systems, acid gas removal equipment, and state-of-the-art gas removal systems, even heavily sour flare gasses can be a useful stream of energy.

In short: Safety above all, materials second, and the process last.

With all these components correct, recovery of sour flare gas not only becomes possible, but lucrative.