Why Associated Gas Recovery is the Key Pathway for Net-Zero in the Oil & Gas Industry

The Oil and Gas industry still emits high volumes of methane through the practice of associated gas flaring. The World Bank 2024 Global Gas Flaring Tracker reports shows that 2023 saw the highest volume of methane gas flaring among the years 2019-2023. The volume of associated gas flaring in 2023 was 148 billion. The gas flaring resulted in 381 million tonnes of CO2.

In 2023, 381 million tonnes of CO2 gas was emitted due owing to of high volume of gas flaring. 2023 was the highest year of unnecessary gas venting since 2019. CATF sees this as one of the largest blind spots in global methane mitigation.If associated gas is flared and vented as it is today, the oil and gas industry cannot, and will not ever be able to achieve net-zero targets.

Why Associated Gas Recovery is Necessary

Environmental Effects

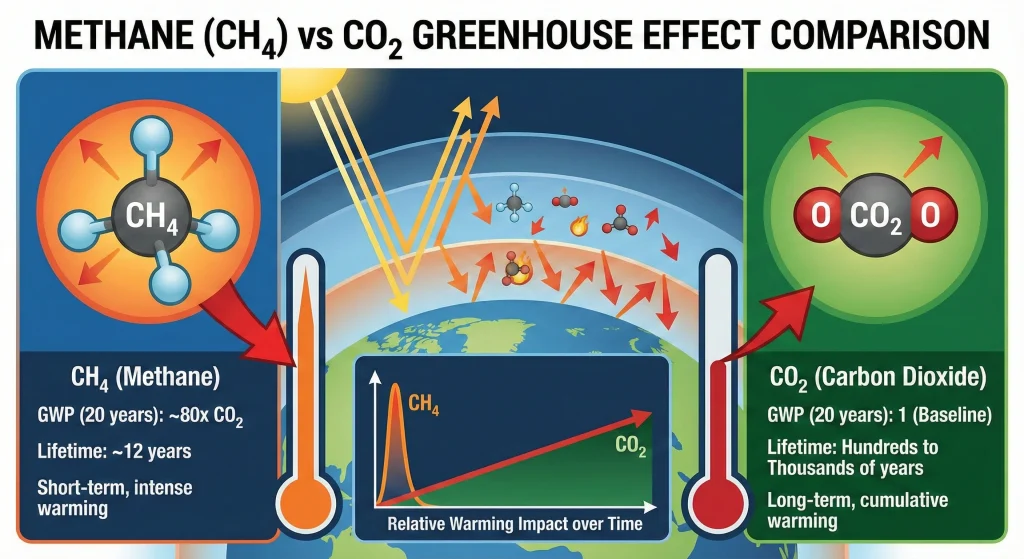

When methane is burned, it creates carbon dioxide. It’s also possible that the burning could create more methane. One way that this could happen is through incomplete burning. However, collecting the gas after it has combusted is the best way to reduce methane emissions because you can also get the carbon dioxide and methane that will be released if you don’t capture it. This approach has been acknowledged by the United States Department of Energy and the CATF to be the best way to eliminate methane emissions.

Economic Value

Gas associated with oil plays a vital economic role apart from its environmental impact. As a Global Gas Flaring Reduction (GGFR) report from the World Bank notes, the massive amounts of associated gas flaring and the greenhouse emissions from it also signal the incalculable waste of energy and economic resources. Capturing and utilizing this gas urgently to provide steady and reliable electricity to the energy-deficient areas of the world and improving their local energy security are key to advancing their regional development and economic growth.

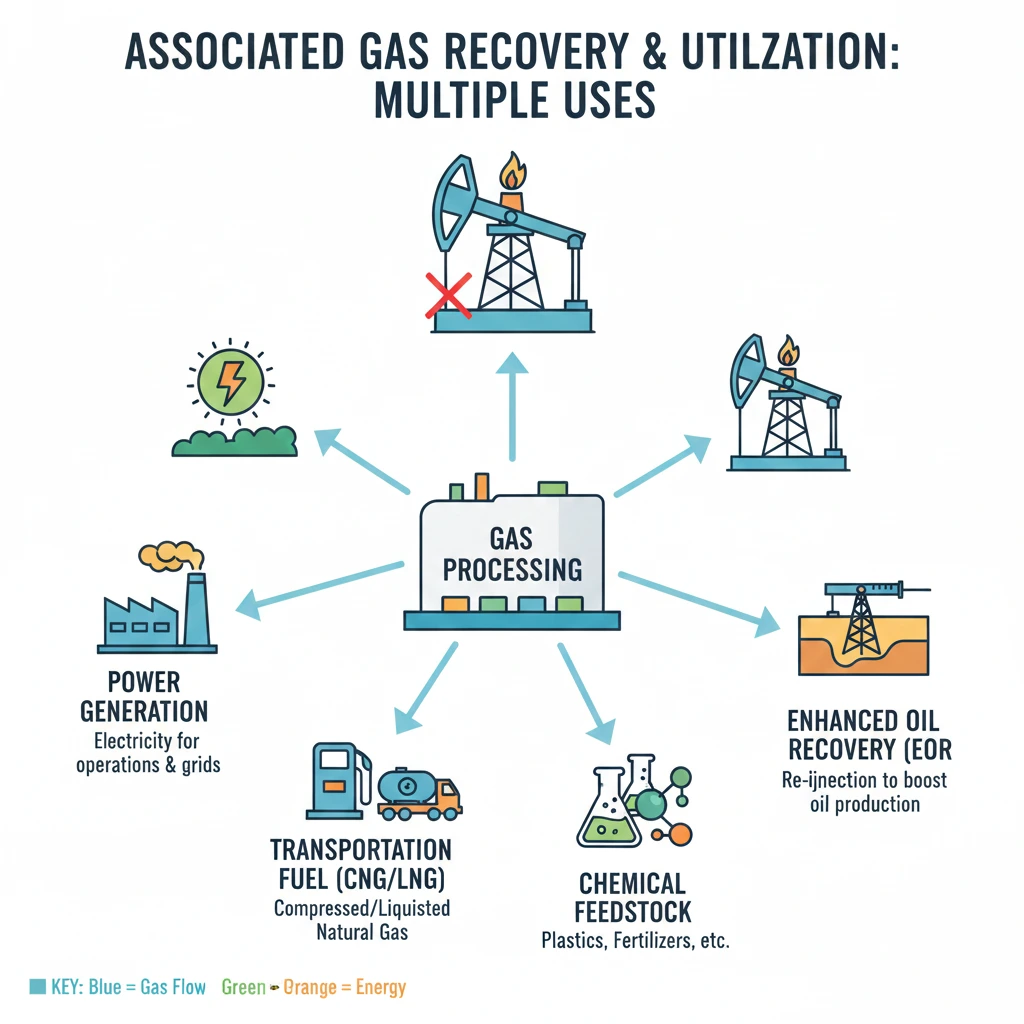

In oilfield operations, the recovered gas reserves the use of diesel and other traditional fuels, thereby cutting operational costs, and reducing emissions. Also, recovered associated gas and chemically equated to CNG, LNG, and electricity and other feedstock with the oil-enhanced oil recovery potential or be used to directly to depleted oil recovery reservoirs. These savings give companies the potential to mitigate methane, reduce other GHG emissions from the atmosphere, and repurpose out methane from atmosphere to a simplified and resource the economy It’s potential savings GHG emissions. repurpose methane from atmosphere. It’s potential savings GHG emissions. Gas recovered from oil to the GIN targets and economic savings targets.

Regulatory Pressure

There are more rules from all over the world regarding the associated gas recovery. Publishing these regulations was the first of the EU’s new rules. The EU wanted to be the first to regulate Methane and demand Oil and Gas Actors to use a whole new system called “MRV (Measurement, Reporting and Verification), Methane for measurement of emissions and Reporting to the EU in these new systems.” The U.S. EPA has its own regulation venting and flaring of gas and has implemented what has to be done and what is to be done to avoid getting fined and sued over these regulations. The World Bank has an initiative called ZRF2030 which has become the gold standard in the industry and is focused on achieving zero routine flaring. Companies in the gas and oil industry will have no options in meeting the new investment and burning oil regulations. These companies need to be compliant in the gas and oil industry if they are to have a future as buyers and sellers. Companies all over the world will be looking more to these OGMP 2.0 standards. Companies not meeting these standards will be ‘cut off’ from profitable investments, loan and debt options, and will be ‘cut off’ from selling their oil and gas. Therefore companies are not meeting the standards companies all over the world will be looking more to these OGMP 2.0 standards.

So oil and gas companies will encounter regulatory fines and penalties but more importantly they will encounter lost profits due to increased carbon costs and burning restrictions. So oil and gas companies will encounter not meeting increased carbon costs, lost restrictions on burning oil, and new rules on international markets. Over the last few years gas recovery has become an “Optional” measurement as an industry standard.

Reasons Why Associated Gas Recovery is Difficult

Although associated gas recovery is critical for gas flaring reduction and methane mitigation, it faces multiple operational challenges:

Technical Difficulties

Offshore associated gas contain multi-phase fluids, such as H2S, water, liquid hydrocarbons, and CO2, and form collections of separated gas streams that have to be separated, compressed, and condensed without any losses to the sor, flash, cascade, and evaporative cycles. Gas production at the wellhead tends to be highly variable. This might be due to the wellhead being a marginal well, or it might be due to the depletion of the gas reservoir. Offshore recovery projects are much more technically complex that onshore recovery projects because the presence of multiphase flow and impurities greatly increase the maintenance and operational difficulties.

Equipment Challenges

Offshore platforms always have extremely limited space. The deck cannot accommodate big equipment for recovering slack/separation liquefaction. The equipment experiences severe conditions while it is left outside. For example, high salt spray, humidity, storms, and vibrations of the equipment can lead to their rapid corrosion and wear, then the equipment could fail. To mitigate some of these concerns, recovery systems utilize modular skid-mounted systems. These systems can have remote and online MRV, remote monitoring and measurement, streamlining compact systems to be reliable and adaptable to multiple environments. Design of these systems is high-performance, compact, and very complex, posing high standards to be met for fabrication and installation.

Economic Factors

Associated gas recovery involves significant upfront investment, including compressors, condensation systems, liquefaction units, and installation costs. However, recovered gas can be directly used for power generation, CNG/LNG supply, or as chemical feedstock, generating rapid returns. Companies can also leverage carbon credits, green financing, and voluntary carbon markets to reduce capital costs and improve ROI. Despite the strong economic potential, initial capital requirements and technical complexity remain key obstacles to deployment.

Mature Methane Mitigation Solutions

Kaitian Gas offers comprehensive engineering solutions covering the full lifecycle from design and construction to operation. Mainstream associated gas recovery technologies include:

Flare Gas Recovery (FGR) Systems

Compressing, separating, and reusing gas to feed fuel systems or generators, achieving gas flaring reduction. Kaitian Gas provides modular skid-mounted solutions for rapid deployment and remote monitoring, combined with online MRV systems for verifiable emissions data.

Mini-LNG / Small-Scale LNG

For remote oilfields or small FPSO platforms, small-scale liquefaction units allow rapid liquefaction and onshore transfer via mini-LNG vessels, achieving energy recovery and carbon reduction. Modular design shortens installation cycles and lowers retrofit costs.

CNG / Compressed Gas Transport

Suitable for medium-to-short distance gas delivery, compressed gas is transported to end-users or power stations safely and efficiently. Kaitian Gas provides complete compression, storage, and monitoring systems.

Reinjection / Enhanced Oil Recovery (EOR)

Associated gas can be reinjected into reservoirs to improve recovery while reducing direct emissions. Kaitian Gas offers customized injection solutions for high-pressure fields, combining geological evaluation, injection equipment design, and long-term monitoring.

Gas-to-Power

Directly using associated gas to drive internal combustion engines or gas turbines for electricity generation is the fastest and most economical solution. Kaitian Gas provides end-to-end services from design, equipment selection, installation, and operation.

These mature technical pathways, combined with Kaitian Gas’s modular engineering and MRV data management, allow companies to reduce flaring, achieve methane mitigation, and convert wasted gas into substantial economic benefits.

Why Associated Gas Recovery is the Key Pathway for Net-Zero

Associated gas recovery is essential for achieving net-zero in the oil and gas industry, for four main reasons:

Maximum short-term emission reduction potential

Flaring and venting are major sources of CO₂ and methane emissions in the oil and gas sector. Deploying FGR, mini-LNG, or gas-to-power systems can quickly and significantly reduce emissions, offering a cost-effective, high-impact pathway.

Mature technologies ready for deployment

FGR compression systems, mini-LNG liquefaction units, CNG transport, and gas-to-power systems have been widely deployed globally. Modular, skid-mounted designs and remote monitoring enable rapid deployment without long trial periods.

Significant economic benefits

Recovered gas can be used for power generation, fuel replacement, liquefaction for sale, and carbon credit generation. Strategic investment and operation planning allow rapid ROI, transforming environmental responsibility into tangible economic value.

Increasingly mandatory regulatory requirements

With the implementation of the EU Methane Regulation, U.S. EPA Methane Rule, OGMP 2.0, and ZRF2030, associated gas recovery has evolved from optional to essential for market access. Methane mitigation is now a baseline requirement for ESG compliance, emission reduction, and international market participation.

In summary, associated gas recovery combines high emission reduction potential, technical feasibility, economic return, and regulatory compliance, making it one of the most direct and effective measures for oil and gas companies to achieve net-zero.

Conclusion

The recovery of associated gas, gas flaring reduction, and methane mitigation are the pillars of achieving net-zero in the oil and gas industry. Whereas the rest of the pillars will take a long time to implement, having the recovery technologies available will yield the best net-zero targets in the limited time frame. Recovery technologies are not only economically viable, but are also becoming a necessity with the directives of the global community.

Therefore, there are indeed multiple options for improving associated gas recovery. By improving associated gas recovery processes, even in the face of high costs for onshore and offshore operations and high market uncertainty, companies can continuously reduce emissions, recover value, and create potential markets.